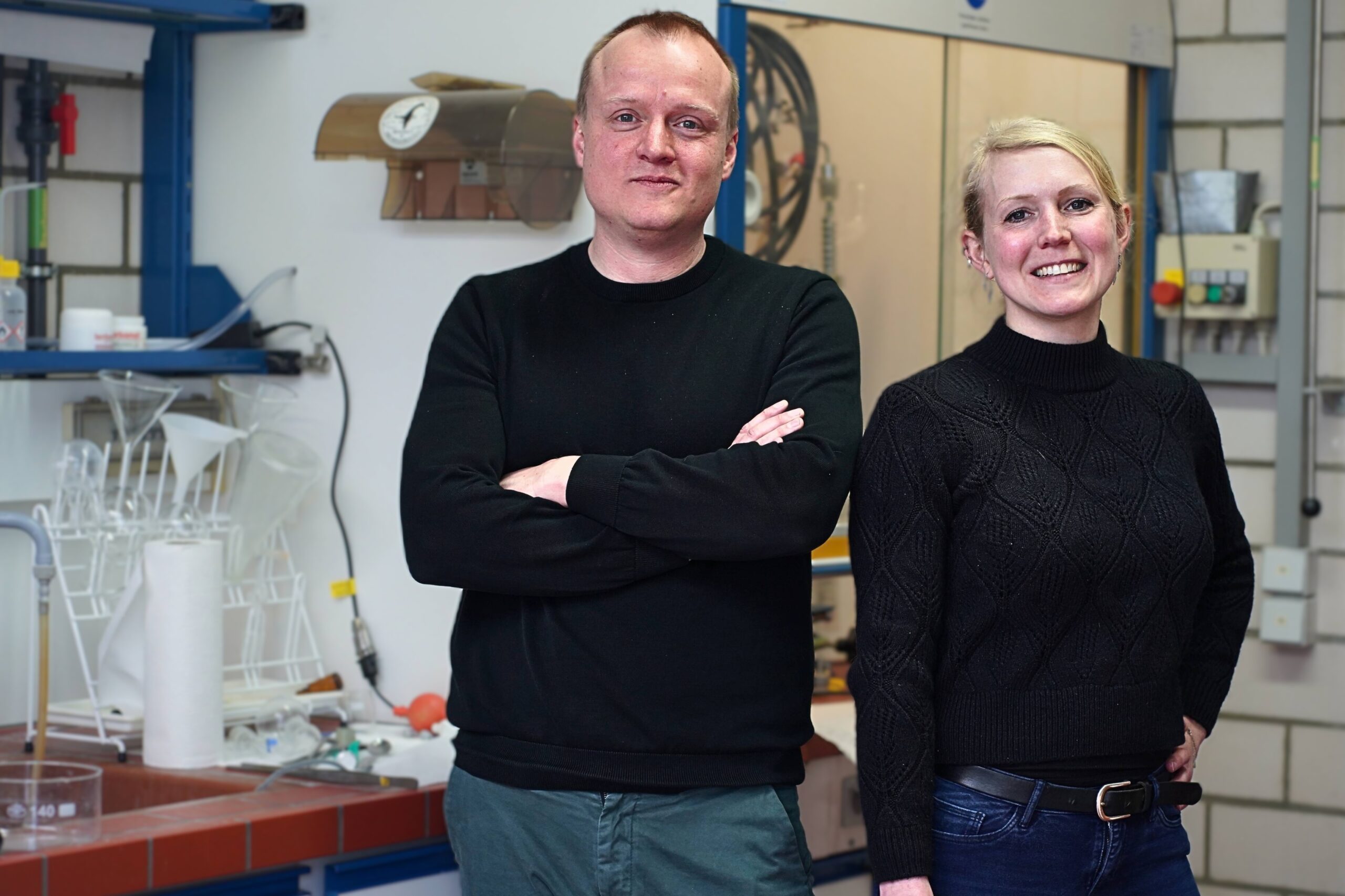

All it took was a flash of inspiration – now they want to change Europe’s energy storage systems: Dr. Pascal Lerner and Dr. Stephanie Dolique Picture: Heike Jüngst

How does a spontaneous question become a climate-friendly technology with global market potential? Stephanie Dolique and Pascal Lerner, two young scientists at TU Darmstadt, show how to turn a special chemical topic into a real start-up story – with passion, patents and the desire to make Europe less dependent on Asia. Borionics is a story about electricity storage, entrepreneurial spirit and the great art of not letting the right moment pass you by.

It all started with one sentence: “Why aren’t you doing anything with it?” This question from Pascal Lerner to Stephanie Dolique was the spark that ignited the idea. What began as a research curiosity developed into a genuine start-up vision: Borionics. The two met at the TU Darmstadt. Stephanie, the research-oriented chemist, and Pascal, the business-minded industrial engineer specializing in chemistry, complemented each other perfectly. Together they dared to do something that is still rare in Germany: take the step from science into entrepreneurship.

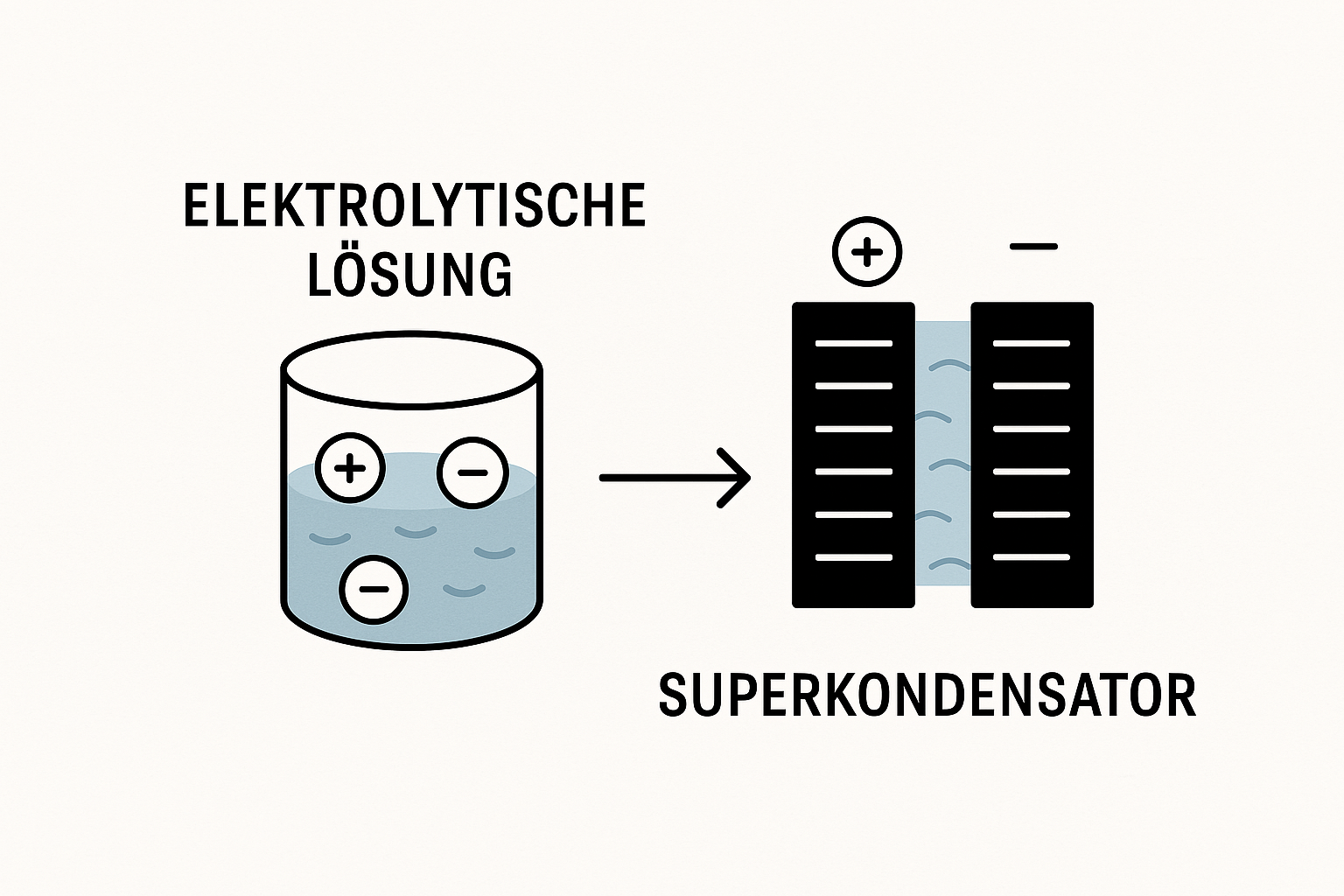

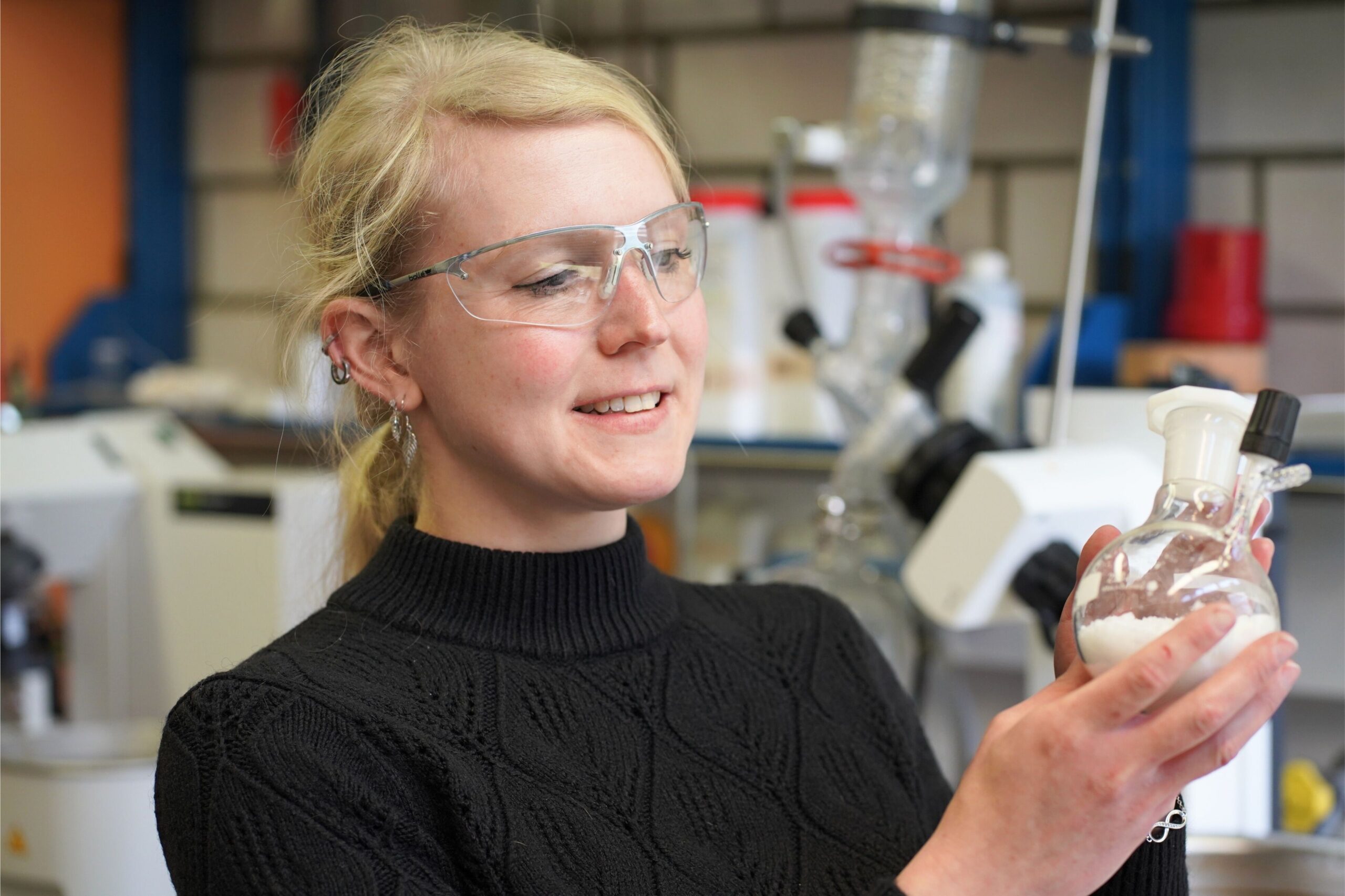

What are they actually doing? They are developing an innovative electrolyte salt for supercapacitors – a key component that significantly improves the performance and service life of these energy storage devices. Their solution is based on an electrolyte salt and a particularly environmentally friendly manufacturing process that simultaneously saves costs and converts problematic waste materials from industry into recyclable, useful materials. “I didn’t want my research to just disappear into a drawer,” says Stephanie today. “So I made the decision: I’m going down the start-up route.”

From test tube to application

Supercapacitors are not new – but what Borionics is getting out of them sounds promising. The two researchers are developing a new electrolyte salt, the heart of every supercap unit. This salt should make it possible to store energy faster, safer and for longer – while also being cheaper and more sustainable to produce. “We even recycle climate-damaging waste materials from Teflon production for synthesis,” explains Pascal. “This is not only cost-efficient, but also makes a real contribution to the environment.” The salt increases conductivity by up to 30 percent compared to the state of the art, is resistant to high temperatures and is almost completely recyclable. This makes it not only a technological advance, but also an ecological promise.

Supercapacitors: fast, safe, versatile

Supercapacitors don’t just store energy – they sprint with it. They can charge or discharge within seconds. This makes them ideal for applications in electromobility, for example to cushion power peaks when starting up, in industry, for example in electric arc furnaces in steel production or in energy systems as intermediate storage for power grid fluctuations. Unlike batteries, supercapacitors are non-flammable, low-maintenance and durable. They are not a competitor to batteries, but their ideal partner. “The combination of battery and supercap is like a marathon runner with a sprinter at his side,” says Stephanie.

Three patents, one mission

Three patents, one missionBorionics’ technology is protected by three patents – including one for the substance itself, one for the application and one for the manufacturing process. At the heart of this is a new type of anion: [M+ BF3CF3-]. “It’s not just a new salt, it’s a game changer,” explains Pascal. “Production is so cost-effective that we can compete with Asian producers – with significantly higher environmental compatibility.”

From the university lab to the world: the path to a start-up

TU Darmstadt is more than just a place of research – it is also a springboard for innovations that lead to a spin-off. Stephanie and Pascal started in 2017 with the support of the Pioneer Fund, followed later by a Hessen Ideas Scholarship, the TU Ideas Competition and finally the VIP+ program of the Federal Ministry of Education and Research BMBF. That was decisive. “Without VIP+, we would never have been able to expand the team,” says Stephanie. Daniel Franz and Lars Sondershausen joined the team – experts in process engineering and electrochemical characterization. Experienced mentors were also found: biochemist Prof. Harald Kolmar from the Department of Chemistry and Dr. Klaus Dieter-Franz, former department head at Merck. “They really helped us to take entrepreneurship in science seriously.”

Impact: More than just energy

Borionics wants more than just more efficient supercaps. The team wants to make Europe less dependent on the Asian market – and at the same time improve the ecological footprint of energy storage systems. “It’s absurd that almost all electrolyte salts come from Asia – and are expensive, harmful to the environment and difficult to recycle,” says Pascal. “We offer a local, resilient and sustainable alternative.” The ecological impact is demonstrated by less waste, better recyclability and CO2-saving synthesis. Economically through cheaper production and competitiveness on the global market. Socially through the strengthening of European supply chains and innovative strength.

The market is calling – but it remains complicated

Despite its progress, Borionics faces typical hurdles faced by German chemical start-ups. Capital requirements are high and investment phases often take up to ten years. At the same time, approval procedures are time-consuming and regulatory requirements are complex. The shortage of skilled workers is also noticeable – especially in the interdisciplinary field. Added to this is the reluctance of private investors: Only 0.2 percent of venture capital in Germany flows into chemistry. “Many investors are afraid of the long development time,” explains Stephanie. “But we believe that our impact justifies the risk.”

The first prototype is already ready

The electrolyte with the new salt was successfully validated in collaboration with Skeleton Technologies. Skeleton – one of the largest supercap manufacturers in Europe – is even planning to build a prototype with Borionics material. At the same time, Borionics is working with E-Lyte Innovations on a quality standard. “We don’t supply a battery or a supercap,” says Pascal. “We supply the ingredient that makes everything better.”

The next steps

The next stepsWith EXIST funding, Borionics wants to bring the process to series production. The aim is to establish scalable production and achieve market quality for the salt. The foundation of Borionics GmbH is the logical next step. In five years, the team wants to be a local manufacturer in Germany supplying electrolyte salts for supercapacitors and batteries – either directly or via contract manufacturing. “Our dream is a 1,000-ton plant,” says Stephanie. “But above all, we want Europe to finally get back into the chemical production game with confidence.”

And the name?

“At first we called our project Boratolytes. Until someone said it was reminiscent of the movie character Borat,” laughs Pascal. The current name Borionics is a promise: For clean energy, made in Germany. Or as Stephanie puts it: “We’re not developing rocket science. But we are making it possible to store electricity more intelligently.” And sometimes that might be enough to change the world.

Author: Heike Jüngst